WIRE ROPE GRIPS USER GUIDE

What are wire rope grips used for?

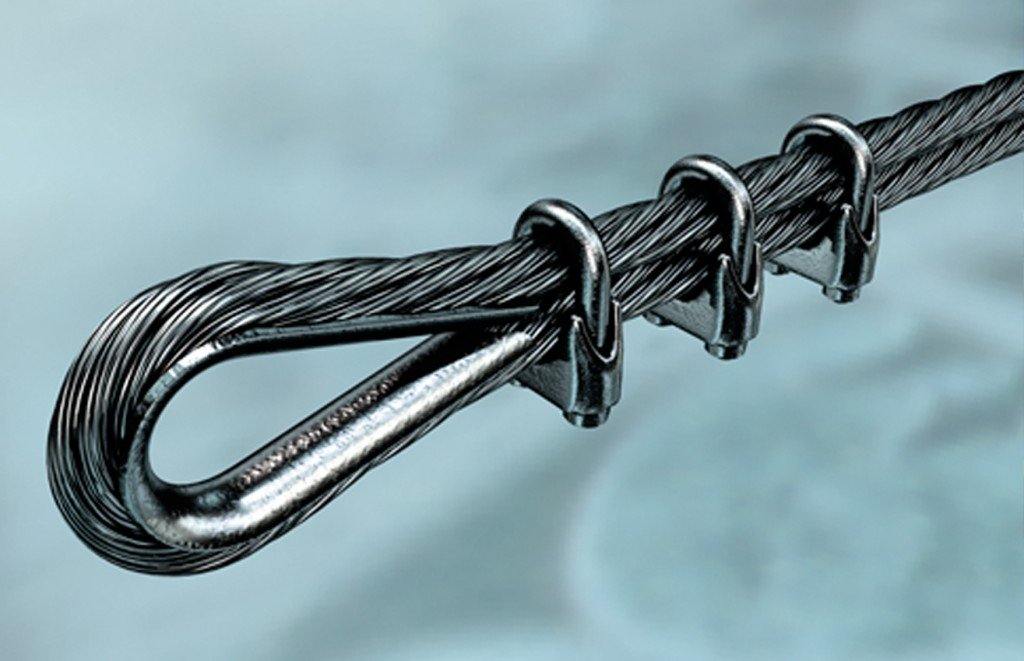

Wire rope grips are a fitting that can be used to create an eye or loop termination at the end of a wire rope. The only tools required are something to tighten the nuts, some heavy-duty tape to stop the rope unravelling and the knowledge to fit them correctly. They are available in a range of types including Australian standard, commercial, US standard and stainless steel.

Correctly fitting a wire rope grip

To achieve maximum efficiency, you need to ensure that the correct type of wire rope grip is selected and fitted correctly. Many wire rope grips are not suitable for lifting applications. Measure the rope diameter and use a wire rope grip of the same size as the rope. If the wire is plastic coated remove the coating, measure and fit only to the metal part of wire rope. The u bolt of the grip must be fitted on the dead side and the saddle on the side of the live line. The correct placement and tightening of the grips on the rope are essential. A minimum of 3 grips should be used for all eye terminations. If not tightened enough the wire rope can slip through the grips and cause the equipment to slip. If overtightened it could cause damage to the wire rope and early failure.

What do I need to check?

Ensure that all markings are clear and that there are no cracks, rust, nicks, cuts pitting etc. Check that the nuts are tightened correctly and that the grip is fitted correctly to the rope. You should never repair a wire rope grip by welding, heating or bending as this may affect the performance. A wire rope termination made with wire rope grips must be inspected regularly and before every use.

How not to use wire rope grips

Wire rope grips should not be used for making terminations on live running ropes. Live running rope are ones that apply force to a moving object or where the rope is required to support persons or dangerous or substantial loads. Wire rope grips should not be used where there is a possibility of the rope having to be lengthened at that end.

The grips in a connection

The efficiency of a wire rope assembly with wire rope grips depends on the number per connection, correct placement, and the care and skill in the fitting and tightening of the grips. Please obtain expert advice on the number of wire rope grips per connection. The grips in a connection should be spaced evenly along the wire rope at distances between adjacent grips of approximately six times the rope diameter.

Also known as: wire rope clips, cable grips, steel wire rope bulldog grips, wire rope clamps, duplex rope grips, simplex grips.

All Lifting have a wide range of wire rope grips available. Need to source wire rope grips for your next project? These are available at our online store.

Not quite what you’re after – Checkout our article about wire rope fittings

Quick Tips:

- Using wire rope grips reduces the working load limit to 80%

- Make sure you have the correct size for the rope

Check-out our online store today, which includes 1,500+ lifting, rigging and height safety products including wire rope grips, lifting slings, blocks, swivels and sheaves and much more.